Understanding the Importance of Your Trailer Axle

A trailer axle is an essential component of any trailer setup. It functions as the central shaft for a rotating wheel or gear, essentially serving as the backbone that supports your trailer’s load. The axle ensures smoother rides and better load distribution, improving the overall safety and functionality of your vehicle. Recognizing the needs and specifications for your trailer axle can make a significant difference in its performance and longevity.

What Does a Trailer Axle Do?

The axle is the crucial link that connects the wheels to the trailer frame. It bears the weight of the cargo and distributes it evenly across the wheels. Without a well-functioning axle, you could face numerous issues, such as uneven tire wear, reduced braking efficiency, and poor handling. Therefore, understanding the role of the trailer axle is fundamental for maintaining the robustness and efficiency of your trailer.

Types of Trailer Axles

There are primarily two types of axles commonly found in trailers: leaf spring axles and torsion axles. Each has its specific characteristics and advantages.

Leaf Spring Axles

Leaf spring axles are one of the oldest and most widely used types of axles. They consist of multiple layers of metal, called leaf springs, stacked together to form a flexible yet durable suspension system. These axles are known for their load-carrying capacity and durability, making them a staple for heavy-duty applications. They are relatively easy to maintain and can handle a wide range of weight capacities.

Torsion Axles

Torsion axles differ from leaf spring axles in their use of a torsion bar mechanism instead of metal leaf springs. The torsion bar provides independent suspension to each wheel, which leads to a smoother ride and improved handling. Torsion axles are also generally lighter and require less maintenance, making them suitable for lighter loads and trailers that don’t face severe terrain.

Signs Your Trailer Axle Needs an Upgrade

Recognizing when your trailer axle needs an upgrade is crucial for both safety and performance. Look out for signs such as uneven tire wear, noises during travel, and reduced ride quality. If you notice your trailer swaying more than usual or if the axle shows visible signs of rust and damage, it might be time to consider an upgrade. Ignoring these signals can lead to greater wear and tear on other components, escalating repair costs in the long run.

When to Upgrade Your Trailer Axle

Knowing when to upgrade your trailer axle can save you a lot of time, money, and potential safety hazards.

Indicators of Wear and Tear

Signs of wear and tear include visible corrosion, cracks in the axle tube, and loosened mounting brackets. Regular inspections can help identify these issues early, allowing for timely intervention before catastrophic failure occurs. Consistent exposure to harsh environments can accelerate the degradation process, making frequent checks even more important.

Performance Issues and Safety Concerns

If you’ve been experiencing reduced braking efficiency, poor handling, or unusual noises, these are clear indicators that your trailer axle may be compromised. Safety should always be a primary concern, and a deteriorating axle can pose significant risks to both the driver and other road users. Upgrading your axle can resolve these performance issues and restore your trailer to optimal condition.

Adapting to Increased Load Requirements

As your hauling needs change, your existing trailer axle might not be sufficient to handle increased loads. Overloading an under-capacity axle can lead to premature failure and unsafe travel conditions. Therefore, upgrading to an axle with a higher weight capacity can accommodate heavier loads and ensure a stable, safe journey.

How to Choose the Right Trailer Axle for Upgrading

Choosing the right trailer axle involves several key considerations to ensure compatibility and performance.

Determining the Appropriate Weight Capacity

First and foremost, you need to determine the required weight capacity for your axle. Examine the gross vehicle weight rating (GVWR) of your trailer to align it with an appropriately rated axle. Overestimating or underestimating the weight capacity can lead to inefficiencies and potential hazards, so accuracy is crucial here.

Comparing Different Materials and Designs

Different materials and designs offer distinct advantages. Steel and aluminum are the two most common materials used for axles, each with its pros and cons.

Steel vs. Aluminum Axles

Steel axles are renowned for their strength and durability; they can handle heavy loads and are less susceptible to bending and deformation. However, they are also heavier and can be prone to rust. Aluminum axles are lighter and resist corrosion but may not offer the same level of strength as steel axles. Evaluate the specific requirements of your trailer and load to make an informed decision.

Straight vs. Drop Axles

Straight axles provide consistent ground clearance and are often used for trailers carrying evenly distributed loads. Drop axles, on the other hand, lower the bed height of the trailer, making loading and unloading easier. Choosing between straight and drop axles depends on your specific loading needs and the type of terrain you frequently navigate.

Considering Compatibility with Your Trailer

Compatibility is a critical factor when upgrading your trailer axle. Ensure that the new axle aligns with your trailer’s suspension system, braking components, and mounting brackets. A mismatched axle can lead to poor performance and additional modifications, complicating the upgrade process.

Understanding when and how to upgrade your trailer axle can significantly enhance your trailering experience. By adhering to these guidelines and recognizing the signs early, you can maintain a safer and more efficient trailer setup, providing peace of mind on every journey.

Steps for Upgrading Your Trailer Axle

Preparing for the Replacement Process

Tools and Materials Needed

Before diving into the replacement process, ensure you have all required tools and materials on hand. You’ll need basic hand tools such as wrenches, pliers, and a socket set, along with specialized items like a jack, jack stands, and a torque wrench. Additionally, make sure you have replacement parts, including the new trailer axle, new mounting hardware, and possibly new hubs and bearings. Preparing these items in advance can streamline the upgrade process and prevent unnecessary delays.

Safety Precautions to Take

Safety should be your top priority when working on your trailer. Begin by parking your trailer on a flat, stable surface and engage the parking brake. Place wheel chocks in front of and behind the wheels that will remain on the ground to prevent any movement. Always use jack stands to support the trailer instead of relying solely on a hydraulic jack. Wearing safety gloves and protective eyewear can further safeguard you from potential injuries during the axle replacement process.

Removing the Old Trailer Axle

Start by loosening the lug nuts on the wheels attached to the trailer axle you’re replacing. Use the jack to raise the trailer, and then secure it with jack stands. Once the trailer is securely elevated, fully remove the lug nuts and wheels. Next, disconnect any brake lines and wiring connected to the axle. Remove the U-bolts or mounting brackets that secure the axle to the trailer’s suspension system. Carefully lower the old axle and set it aside. Ensuring that you meticulously follow each step will pave the way for a smooth installation of the new axle.

Installing the New Trailer Axle

Aligning and Securing the Axle

Position the new trailer axle under the trailer in alignment with the suspension system. Use the jack to lift the axle into place, ensuring it is centered and properly oriented. Reattach the U-bolts or mounting brackets, securing the axle to the suspension. Use a torque wrench to tighten the bolts to the manufacturer’s specified torque setting, ensuring a secure fit. Proper alignment and securing of the axle are crucial for optimal performance and safety.

Connecting Brakes and Wiring (if applicable)

If your trailer is equipped with brakes, reconnect the brake lines to the new axle. Ensure that the connections are secure and free from any leaks. Reattach any wiring that was disconnected during the removal process, verifying that all electrical connections are intact and functioning correctly. Properly routing and securing brake lines and wiring will protect them from damage and ensure reliable performance.

Go Trailer Parts, an outstanding Chinese trailer parts manufacturer, offers a range of high-quality trailer winches designed to meet various needs in the transportation and travel industries. These winches are essential tools for enhancing the functionality and convenience of trailers, whether for towing campers and RVs in the tourism industry, moving boats to docks or shores in water transport, or rescuing vehicles stuck in muddy or rough terrains during off-road travel. The trailer winches from Go Trailer Parts are built with durability and reliability in mind, ensuring that users can confidently handle challenging towing and recovery tasks.

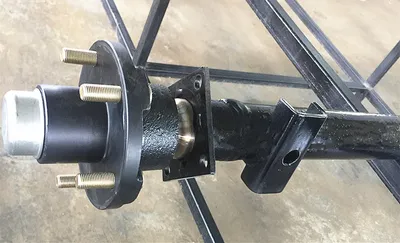

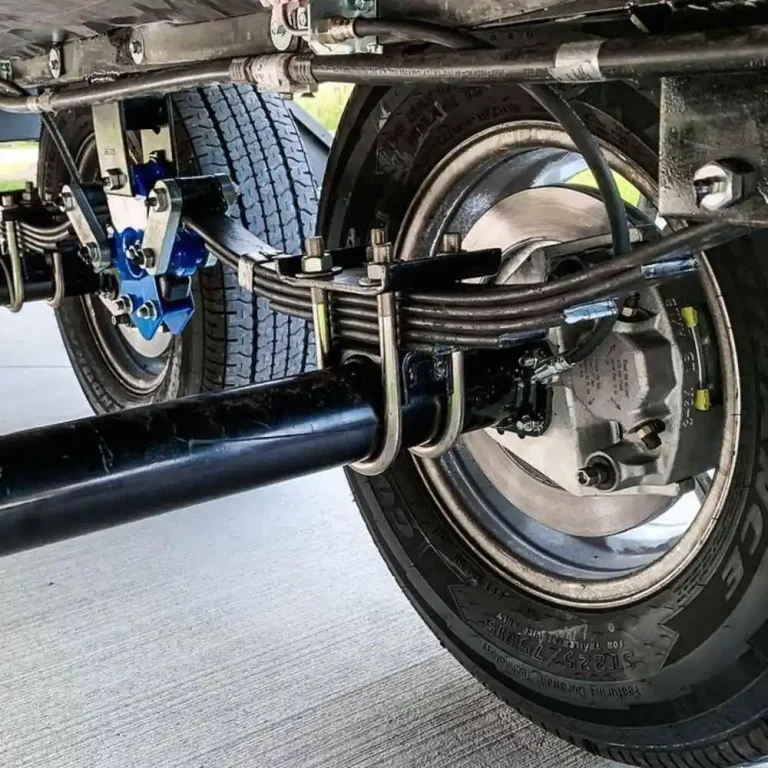

In addition to their practical applications, Go Trailer Parts’ trailer winches are part of a broader product lineup that includes jockey wheels, couplers, axles, springs, and more. The company prides itself on its commitment to safety, quality, and honest business values, supported by a team of professional engineers, senior welders, and experienced workers. With advanced production equipment such as CNC machines, drilling machines, and laser cutting machines, Go Trailer Parts ensures that each winch is manufactured to the highest standards. Its 45mm round non-braked drop axle is engineered for durability and reliability, making it an excellent choice for various trailer applications. Additionally, their Electric brake drop axle 45mm round offers enhanced safety and control, ensuring smooth and efficient braking performance for heavier loads. By choosing Go Trailer Parts, customers benefit from the expertise of a leading manufacturer, avoiding the hassles associated with dealing with intermediaries and ultimately saving time and money.

Maintenance Tips for Your New Trailer Axle

Regular Inspection and Lubrication

To keep your new trailer axle in top condition, conduct regular inspections. Check for signs of wear, damage, or corrosion. Lubricate moving parts such as bearings and pivot points according to the manufacturer’s recommendations. Regular lubrication can prevent excessive wear and extend the longevity of the axle. Keeping a maintenance log can help you stay on top of these tasks and ensure that nothing is overlooked.

Addressing Common Issues Promptly

Even with regular maintenance, issues can arise. Address common problems such as noise, vibration, or uneven tire wear as soon as they are detected. Investigate the cause and take corrective actions promptly, whether it’s tightening loose bolts, replacing worn components, or realigning the axle. Promptly addressing these issues can prevent more significant problems and costly repairs down the line.

Best Practices for Longevity

To maximize the lifespan of your trailer axle, adhere to best practices, including avoiding overloading the trailer and driving within recommended speed limits. Ensure that the axle is correctly aligned and that the trailer’s load is balanced. Performing periodic inspections and keeping the axle, suspension components, and tires in good condition will contribute to the overall longevity and reliability of your trailer axle.