A trailer axle is more than just a metal rod. It plays a vital role in upholding your trailer’s weight and linking the wheels together to guarantee a smooth and secure towing experience. Selecting the axle is key for safety and efficiency as well, as extending your trailer’s lifespan. Now let’s delve into the components of a trailer axle and examine the types on offer.

Trailer Axle Components: The Foundation

1. Axle Beam: The Backbone of the System

The core element is usually a beam crafted from tough steel that supports the trailer and its load by directing the weight to the wheels underneath it effectively. The durability of the axle beam is crucial, for ensuring towing operations – envision it as the foundation that unites all components seamlessly.

2. Hubs: Connecting the Wheels

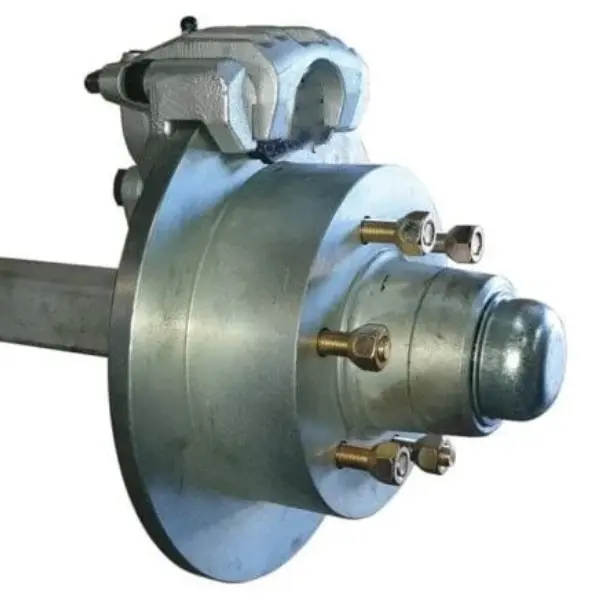

The axle beam is fitted with hubs at both ends to contain the bearings, offering a place for the wheels to be attached and rotated with ease in different designs based on the axle’s type and braking mechanism used.

3. Bearings: Enabling Smooth Rotation

Bearings are placed inside the hubs. They can reduce friction between the hub and the axle to help the wheels turn smoothly.

4. Wheel Nuts: Securely Fastening the Wheels

These nuts secure the wheels onto the hubs. It’s crucial to apply the correct amount of force to avoid any risk of the wheels coming loose while towing a vehicle.

Different Types of Trailer Axles and their Parts: Adding Functionality

1. Lazy Axle: Simplicity for Lighter Loads

“Lazily rolling axle,” a term denoting an axle commonly found in single wheel trailers for transporting light loads due to its uncomplicated design without brakes, in place. Essential components required for the assembly of an axle are as follows:

- Axle Beam: The foundation of the axle.

- Bearings and Hubs: Enabling wheel rotation.

- Wheel Nuts: Securing the wheels.

- U Bolts, Fish Plates, and Axle Seats: For attaching the axle to the trailer’s suspension.

You can purchase these axles and their components from businesses such as Trailer 2000 Parts.

2. Braked Axle: Enhanced Safety for Heavier Loads

Trailers that weigh, more than 750 kilograms need brakes for safety reasons to ensure proper control and stability while driving. Braked axles usually utilize disc brakes because of their performance and easier maintenance procedures. Below are the parts of a braked axle system which includes the use of electric brakes:

- Axle Beam: This is the structural base of the entire system, providing support for all other components.

- Hubs and Bearings: These ensure smooth wheel rotation and are essential for both braked and unbraked axles.

- Wheel Nuts: These fasten the wheels securely to the hubs.

- Brake Drums This is the braking surface for axles using electric drum brakes.

- Electric Backing Plates: These house the brake shoes and electromagnets that are vital for the electric braking system’s operation.

- U Bolts, Fish Plates, and Axle Seats: These components are crucial for attaching the axle to the trailer’s suspension system, ensuring a secure and stable connection.

The makeup of an axle can vary based on the braking system employed – whether it’s disc brakes or electric drum brakes the components used in it are usually driven by factors like trailer weight and intended usage as well, as personal choice.

Consider exploring Go Trailer’s Customization Service to tailor the axle to your specific needs.

Trailer Axle Materials and Construction: Ensuring Durability

The axle beam is usually made with materials such as solid steel to handle heavy loads and tough road conditions effectively. Go Trailer uses high-tensile solid steel for its axle beams to ensure long-lasting performance and dependability, in Australian settings.

Additional Parts for Axle Replacement: Completing the Assembly

When you need to swap out a trailer axle for one, it’s important to make sure you have the parts on hand based on the type of axle you’re working with.

- Axle: The core component.

- Hubs: Housing the bearings.

- Wheel Nuts: Securely fasten the wheels.

- Bearings: Enabling smooth rotation.

- Brakes: If applicable (disc brakes or brake assembly).

- U Bolts: Connecting the axle to the leaf springs.

- Fish Plates: Reinforcing the connection between the axle and the springs.

- Axle Seats: Providing a mounting point for the springs on the axle.

If you require help figuring out the components needed for this task, reach out to the professionals at Go Trailer.

Choosing the Right Axle: Factors to Consider

1. Load Capacity: Matching the Axle to the Weight

The axle needs to bear the weight of the trailer and the heaviest cargo it can carry without going over its limit to avoid potential risks of failure that can be dangerous. Take, for instance, the Hydraulic Brake Axle 50mm Square with a capacity of 2000KG, as a reference point.

2. Load Type: Distributing the Weight Evenly

The kind of weight carried affects how the axle is arranged on a vehicle, such as gravel being spread out differently than heavy machinery concentrated in one area.

3. Trailer Size and Design: Ensuring Compatibility

The size of the axle must align with the trailer’s frame and wheels to avoid issues, like tire damage and unsafe driving conditions that could result in accidents.

Trailer Axle Maintenance: Prolonging the Lifespan

1. Regular Lubrication: Keeping Things Running Smoothly

Regularly greasing up bearings and mobile components is crucial to avoid wearing out and to maintain the functioning of the machinery. It’s important to know the suitable lubricant type and how often it should be applied. Follow the guidelines provided by the manufacturer can help you.

2. Inspections: Identifying Issues Early On

Make sure to check the axle for any indications of wear or harm, such as;

- Uneven Tire Wear: This could indicate axle misalignment or bearing issues.

- Strange Noises: Might suggest bearing problems or loose components.

- Visible Bending of the Axle: Requires immediate attention and likely axle replacement.

3. Brake Maintenance (if applicable): Ensuring Safe Stopping

For braked axles, check:

- Brake Fluid Levels: Ensure adequate fluid for proper hydraulic brake function.

- Brake Pads and Rotors: Inspect for wear and tear.

- Hydraulic Lines: Check for leaks or damage.

- Clean Brake Components: Regularly remove dirt and debris to maintain braking efficiency.

4. Tire Maintenance: Supporting the Axle

- Tire Pressure: Maintaining correct tire pressure is crucial for optimal braking and handling.

- Tread Condition: Regularly check tire tread depth for safe and efficient towing.

When to Replace a Trailer Axle: Recognizing Signs of Wear

Car axles are built to last a long time. However, sometimes they may need to be replaced due to reasons.

- Bearing Failure: Severe damage to the axle shaft due to bearing issues.

- Bent Axle: Compromises structural integrity and requires replacement.

- Upgrading Trailer Capacity: A new axle might be needed to accommodate heavier loads.

Conclusion: A Crucial Component for Safe and Efficient Towing

The axle of a trailer plays a role in maintaining the safety and efficiency of the trailer’s operation. It is important to know its components, types, and maintenance needs so that you can make informed choices. Always prioritize safety when dealing with trailer axles. Don’t hesitate to seek guidance for optimal performance and peace of mind.